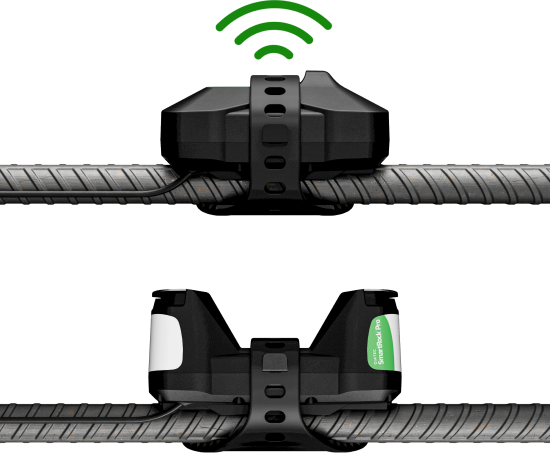

If you are an engineer, construction professional, or contractor, you know how important it is to monitor the strength of your in-situ concrete. That is where SmartRock® Pro sensors come in. SmartRock Pro is a wireless sensor that calculates in-situ concrete strength in real-time, providing you with accurate and reliable data that you can use to optimize your construction process. In this blog, we will explore the key features of this new sensor and explore its potential to enhance efficiency, productivity, and the overall quality of your projects. See how self-calibration will change your concrete projects here! Simple Installation When it comes to design, SmartRock Pro offers simplicity and flexibility. It is a truly wireless sensor that is incredibly user-friendly and easy to install. It consists of two main parts: the antenna (transmitter) and the probe. The probe is embedded in concrete to collect raw concrete data, while the transmitter contains the antenna for wireless communication. The transmitter can be placed at a depth up to 2 in (cm) below the concrete surface to ensure proper transmission of signal to the phone. A cable connects the transmitter to the probe. Self-Calibrating Sensor The SmartRock Pro can automatically detect your pouring time, as it…