Maturity-Based Concrete Strength Monitoring

Cut costs and increase efficiency with SmartRock®, the maturity based concrete strength monitoring sensor

Concrete Maturity

Cut costs and increase efficiency with SmartRock®, the maturity based concrete strength monitoring sensor

Leveraging the ASTM C1074 maturity method, SmartRock measures accurate strength at specific locations within the concrete structure.

Utilizing the ASTM C1074 standard, SmartRock enables users to eliminate costly cylinder break tests, streamline project schedules, and ultimately achieve superior outcomes.

By connecting to Giatec 360™ and/or the SmartRock app, users can remotely monitor their concrete curing process in real time and seamlessly share project data with all stakeholders.

A Truly Wireless Concrete Sensor

Tag and install the sensor on any project in just a few minutes. With SmartRock, our ASTM-standardized sensor, you can accurately measure concrete strength using the maturity method at any time, from anywhere, on any device.

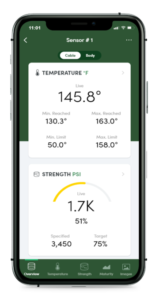

Profoundly Simple-to-Use Mobile Access

The SmartRock app offers real-time access to concrete data on-site through direct sensor communication or remotely via the SmartHub system.

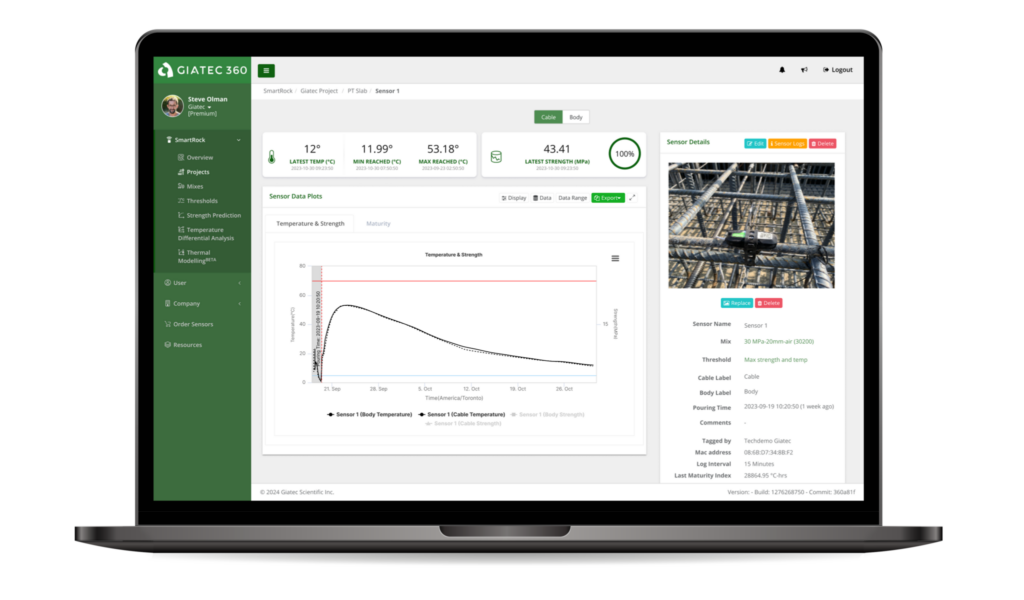

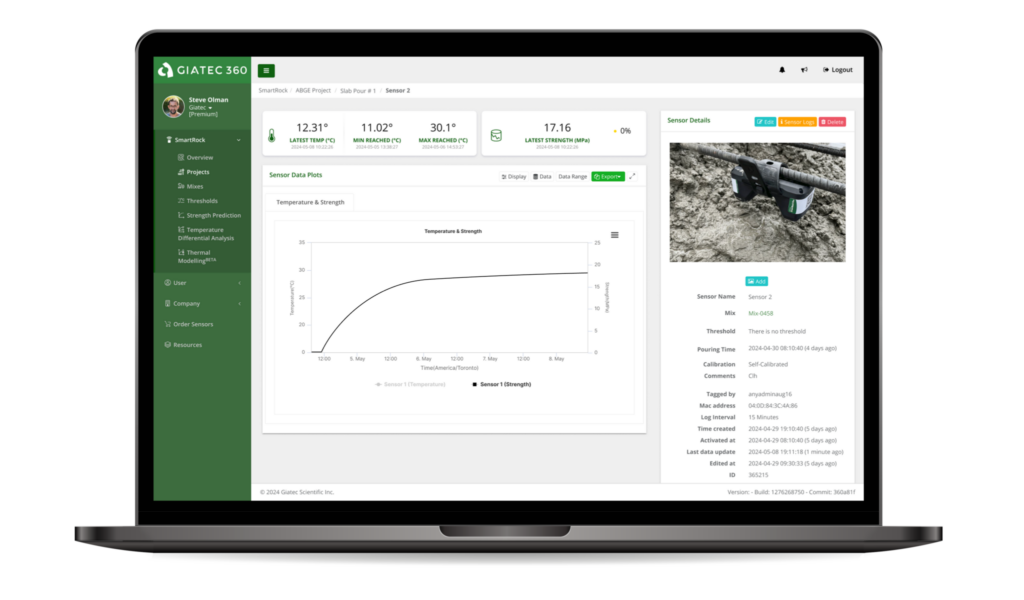

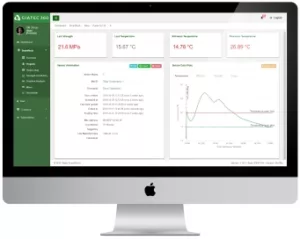

Cloud-Based Project Dashboard

Giatec 360™ is a comprehensive project management tool with advanced data analytics for evaluating concrete mixes, monitoring projects, and gaining detailed insights into strength data. Through Giatec 360, users can:

Optional 24/7 Remote Monitoring Device

SmartRock sensor data is easily accessed and analyzed through direct wireless communication with your mobile device. If you need to access your concrete data without visiting the jobsite, simply install the SmartHub unit in the field and get sensor data automatically collected and sent to you via LTE network.

Built-In Artificial Intelligence Assistant

Roxi is the first machine learning algorithm for concrete materials that has been trained with millions of data points to offer smart suggestions and detect anomalies in concrete performance.

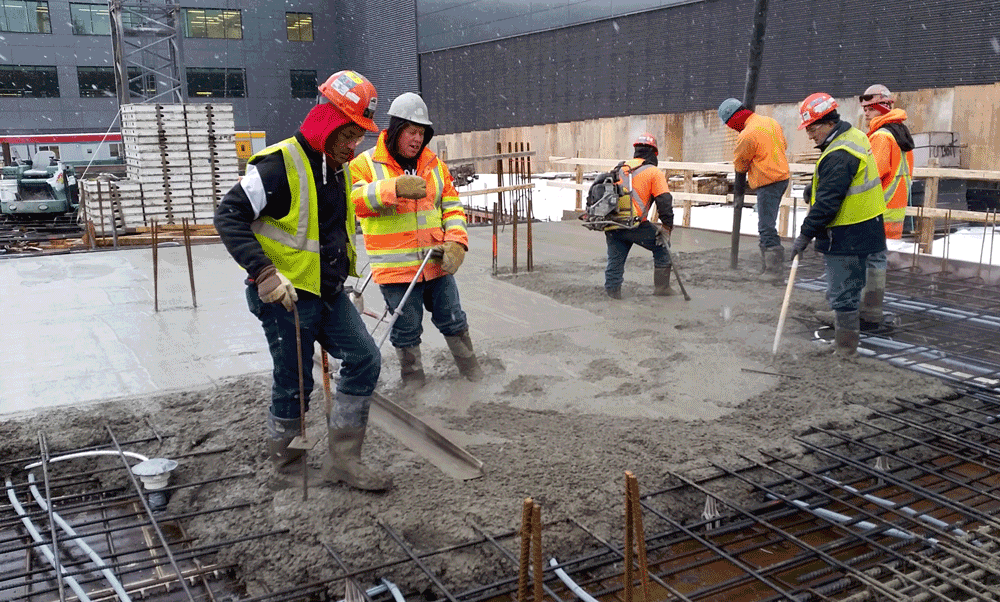

In post-tensioning projects, SmartRock can calculate concrete maturity, aiding in accurate timing of tendon tensioning in slabs, thus reducing the risk of premature tensioning.

Obtaining accurate estimation of in-situ concrete compressive strength with SmartRock helps in reducing the time until the formwork can be removed.

For highway and road projects, using maturity method through SmartRock can cut costs and save time. Lanes can be opened to traffic much faster after repairs.

Today, many states’ Departments of Transportation (DOT) accept the maturity method as an essential tool to understand the strength development of in-place concrete for their infrastructure projects. More specifically, 36 states recognize the method as a reliable and accurate estimation method of concrete strength. This tool facilitates the decision-making process for project managers in terms of their concrete without compromising quality, time, or cost. In this blog, let’s explore how the maturity method works in DOT concrete and construction projects. We will learn how these departments optimize their resources while combatting the pressure of deadline constraints. How does concrete maturity fit into your project? How Is the Maturity Method Used in DOT Concrete and Construction? Let’s understand how the maturity method works. The maturity method is a non-destructive method to estimate the real-time strength development of in-place concrete. Specifically, it works at an early age of less than 14 days. In the 1950s, Nurse, McIntosh and Saul developed a relationship between temperature and time to determine concrete maturity. They called their method the Temperature-Time Factor (TTF). In the 1970s, Freiesleben-Hasen and Pedersen developed a different Maturity Method. This method is based on the Arrhenius equation and is commonly used in…

The maturity method is a convenient approach to predict the early age strength gain of concrete, using the principle that the concrete strength is directly related to the hydration temperature history of cementitious paste.

Schmidt Hammer (or Rebound Hammer) Method The concrete rebound hammer test (often referred to as Schmidt Hammer) was invented in 1948 and is still a popular choice to test the compressive strength of concrete. To use this method, the concrete rebound hammer must first be calibrated against a steel test anvil. Once calibrated, a spring release mechanism is used to activate a hammer which impacts a plunger to drive into the surface of the concrete. After impact, the plunger is locked in its retracted position and a rebound number is recorded (the numbers can range from 10-100). For accuracy, testers should record several numbers. In order to establish a relationship between the rebound number and the compressive strength of concrete, experts usually use the following two methods: ACI 228.1: In Place Methods to Estimate Concrete Strength, or BS EN 13791:2019: Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components. The Principle of the Schmidt Hammer (Concrete Rebound Hammer) Test According to The Constructor the concrete, “rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes.” In other words, the…