SmartRock Sensor

A Complete Solution for Temperature Monitoring

SmartRock Sensor

A Truly Wireless Concrete Sensor

Tag and install the sensor on any project in just a few minutes. SmartRock sensors help to track the changing concrete temperatures in cold or hot weather conditions. With real-time temperature data, you can make the right curing decisions for your structure.

- Wireless and wire-free

- Hassle-free and secure installation using the SmartRock mobile app

- Easy activation with LED light verification

- Designed to withstand the harshest weather and construction conditions

- Directly embedded-sensor-to phone signal range up to 40ft (12m)

- Remote monitoring with SmartHub™

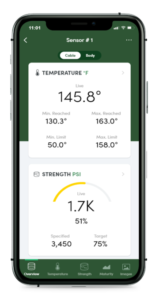

SmartRock Mobile App

Profoundly Simple-to-Use Mobile Access

The SmartRock mobile app provides real-time access to concrete data either on the jobsite through direct communication with the sensor, or remotely via the SmartHub system.- Tag sensors quickly and efficiently via QR code

- Get real-time and remote temperature, maturity, and strength data

- Organize sensors by project and pour/section

- Receive proactive custom alerts and smart notifications

- Create and organize concrete maturity calibration database

- Easily generate complete PDF/CSV reports to share with team members

- Multi-company access to project data

- Free download for Android and iOS devices

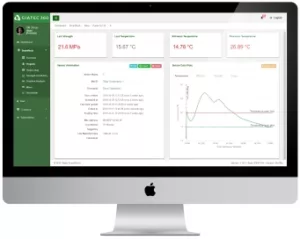

360 Dashboard

Cloud-Based Project Dashboard

Giatec 360 is a comprehensive project management tool with advanced data analytics for evaluating concrete mixes, monitoring projects, and gaining detailed insights into temperature data- Predict concrete temperature

- Obtain real-time concrete temperature data

- Set up thresholds for pours

- Make decisions faster with easy report sharing

- Receive custom alerts and smart notifications

- Manage user access levels to sensitive data

SmartHub™

Optional 24/7 Remote Monitoring Device

SmartRock sensor data is easily accessed and analyzed through direct wireless communication with your mobile device. If you need to access your concrete data without visiting the jobsite, simply install the SmartHub unit in the field and get sensor data automatically collected and sent to you via LTE network.

- Track the status of your pour at anytime, from anywhere, on any device

- Guaranteed uninterrupted data collection 24/7 (unlike other hub devices)

- Never lose project data, even if the SmartHub battery dies or gets damaged on the jobsite

- Flexible onsite installation

- Receive custom alerts and smart notifications

- Completely sync data between your mobile device and Giatec 360 user access levels to sensitive project data account

Roxi AI™

Built-In Artificial Intelligence Assistant

Roxi is the first machine learning algorithm for concrete materials that has been trained with millions of data points to offer smart suggestions and detect anomalies in concrete performance.

- Eliminate human-error and increase confidence in accuracy of test results

- Proactively detect maturity calibration errors

- Predict concrete properties and automatically detect pouring time

- Set-up proactive custom alerts and smart notifications for different thresholds

REST API

Project Data Integration

SmartRock can be easily integrated with any construction project management software. Automatically populate data on concrete quality on your preferred platform to generate action items and triggers on the next steps of your construction project.

- The only concrete IoT sensor integrated with Procore’s dashboard

- Build custom integrations to view and share all SmartRock data directly on your project management software

- REST API to develop customized reports and data analytics

- Manage projects and pouring status in one location

Applications

High Rise

For high-rise projects, concrete temperature monitoring is essential to ensure proper curing, strength development, and prevention of thermal cracking.

Post-Tensioning

Accurate concrete temperature measurement is vital for all post-tensioning projects to avoid premature tension, structural cracks, and blowouts.

Paving

Extend the pavement's service life, achieving desired concrete strength. Reduce the likelihood of premature failures and ensure quality, durability, and sustainability.

Case Studies

Blogs

Important Considerations of Cold-Weather Concreting

Cold weather concreting presents a range of challenges for contractors, particularly when working in very low-temperature environments. One of the primary challenges is the effect of temperature on the concrete’s setting and curing process. As temperatures drop, the hydration process of concrete slows down significantly. This delayed setting and strength gain can lead to construction delays, impacting project schedules and budgets. Engineers must carefully monitor and manage the concrete’s temperature during the placement and curing phases. This ensures the concrete achieves the desired strength and durability. Here are a few important considerations when we are preparing concrete in cold weather.How temperature monitoring is right for your cold-weather projects!Another significant challenge is the potential for freezing temperatures. If concrete is subjected to freezing conditions before it gains sufficient strength, it can lead to severe damage. Freeze-thaw cycles can cause internal cracking and spalling, compromising the integrity of the structure. One can apply several important measures to protect freshly placed concrete from freezing. They can include the use of insulating blankets or the application of external heat sources to maintain the desired temperature. This necessitates careful planning and coordination to ensure the success of the cold weather concreting process.Additionally, cold weather conditions…

Why Is It Important to Cool Concrete in the Summer?

Summer is a busy time for the construction industry. The warm months present a chance to get a lot done, and avoid the extensive challenges that come with cold weather concreting. However, hot weather concreting can also affect the safety and durability of your structure if you do not take measures for concrete cooling in summer. Since the temperature of your in-situ concrete during hot weather directly affects its strength development, here we share five tips that will help you these summer months.Why Is Concrete Cooling in Summer Important? ACI defines hot weather concreting as “one or a combination of the following conditions that tends to impair the quality of freshly mixed or hardened concrete by accelerating the rate of moisture loss and rate of cement hydration, or otherwise causing detrimental results: high ambient temperature; high concrete temperature; low relative humidity; and high wind speed.”When hot weather concreting, there may be serious consequences that can be irreparable under drastic temperatures. Your structure can lose durability if the temperature during hydration is too high due to an early peak in strength gain. One risk you may encounter during hot weather concreting is concrete shrinkage. Shrinkage may be defined as “the reduction of concrete volume due to…

Pouring Concrete in Summer and Winter: What Is The Difference?

One of the most important aspects of concrete strength development and ensuring the integrity of a completed structure is the temperature of the concrete pours during the early stages of construction. We are not always lucky enough to experience perfect conditions for concrete pouring and curing. If the temperature is consistently 60°F (15°C ), it’s likely that you won’t run into trouble, but what happens when you’re faced with more extreme weather conditions? In this blog, we will delve into what is needed when pouring concrete in winter and pouring concrete in summer, as well as the importance of monitoring temperature.Pouring Concrete in Winter According to ACI 306: Guide to Cold Weather Concreting, “cold weather” is defined as three or more consecutive days of low temperatures, specifically outdoor temperatures below 40°F (4°C) and air temperature below 50°F (10°C) for more than any 12-hour period. The water present in concrete causes it to harden through a chemical process called hydration. During this process, the chemicals in the concrete react with water to bind the mixture together. The problem with cold weather is that it slows down this process or stops it completely, negatively impacting the strength gain of the concrete. Furthermore, it’s critical for concrete to set before being exposed to freezing temperatures. If fresh concrete is exposed…